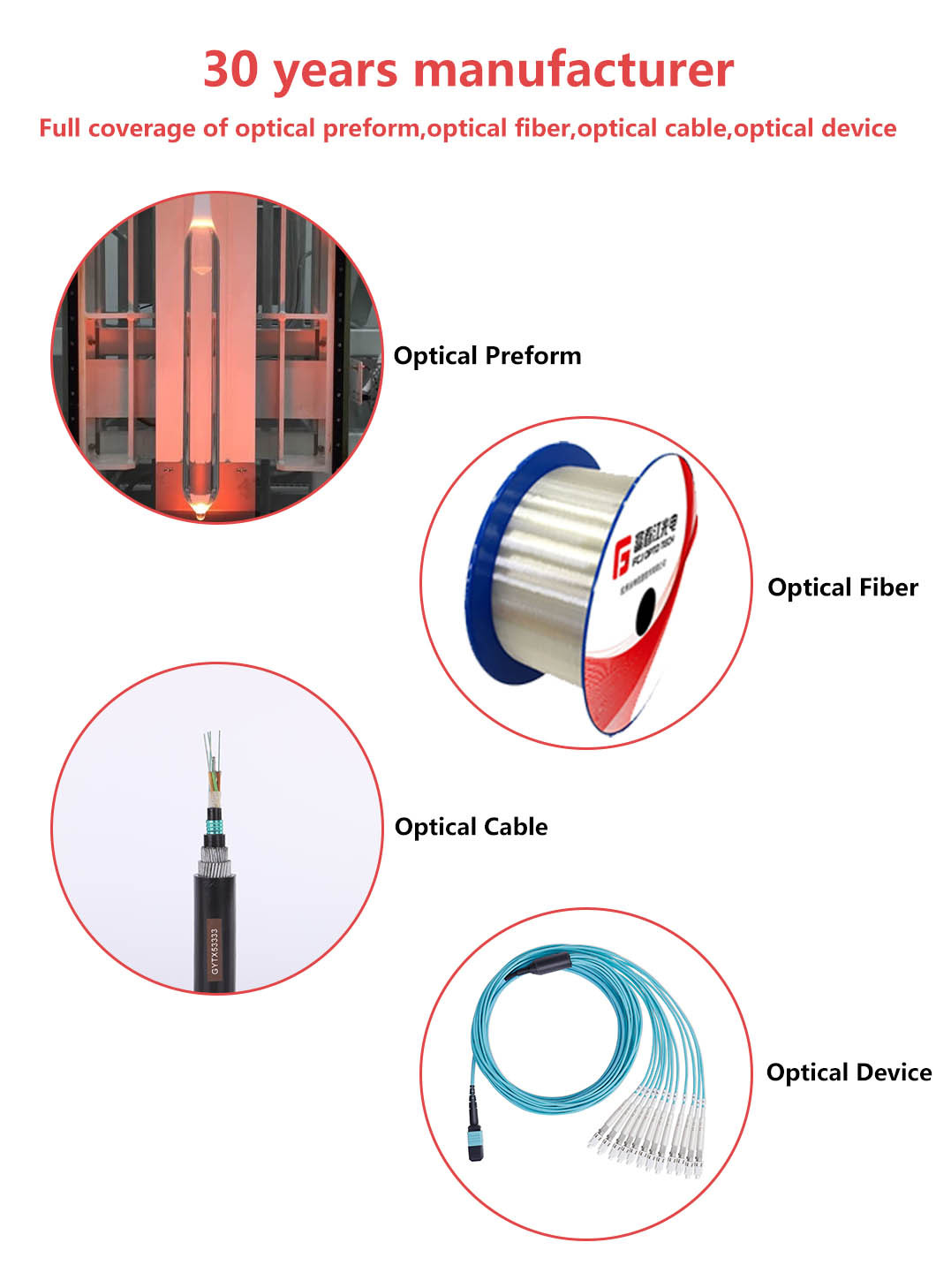

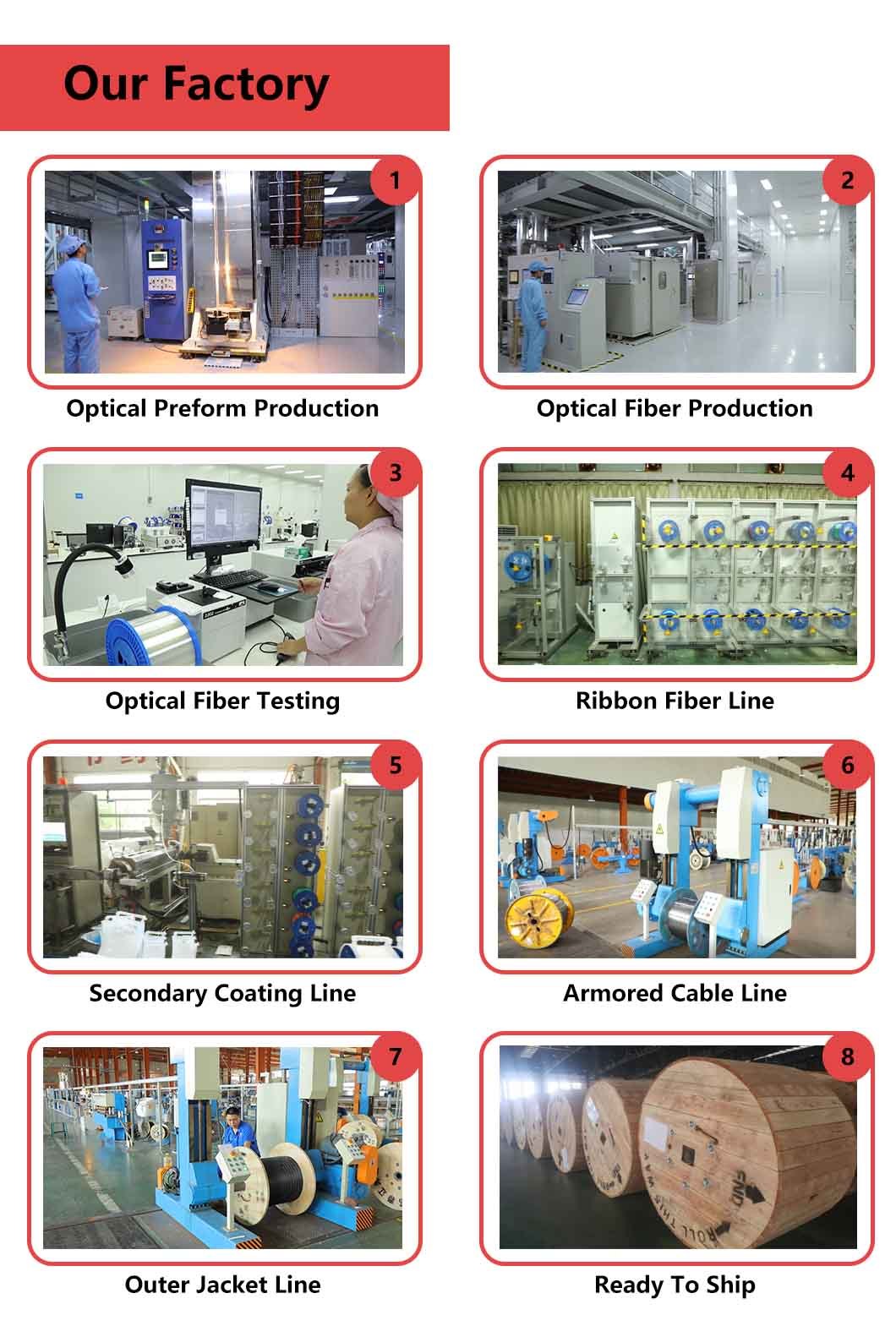

FCJ factory OM2/OM3/OM4 Bend Insensitive Multimode Fibres

- Model

- OM2+/OM3/OM4 Multimode fiber

Item specifics

- Fiber Type

- OM2

- Bandwidth

- 850~1300

- Manufactured By

- PCVD

Review

Description

FCJ OPTO TECH OM2+ Bend Insensitive Multimode Fibre complies with or exceeds ISO/IEC11801OM2 specification, IEC 60793-2-10 type Ala.l Optical Fibre Specifica tion, and TIA/EIA-492AAAB-A detail specification.

FCJ OPTO TECH OM3/OM4 Bend Insensitive Multimode Fibres comply with or exceed ISO/IEC 11801OM3/OM4 specification, IEC 60793-2-10 type Ala.2 and Ala.3 Optical Fibre Specification, and TIA/ EIA-492AAAC/492AAAD detail specification.

|

Features |

Benefits and Applications |

|

Very low macro-bending sensitivity Low micro-bending sensitivity |

The fibre is easier to handle and install without excessive care when storing the fibre, for example, in splicing cassettes Supports installation with small cable bend radii and compact organizers

Facilitates jumper moves,adds and changes |

|

Maintaining compatibility with current OM2+/OM3/OM4 multimode optical fibre Low differential mode delay (DMD) Low attenuation |

Central offices Data centers High performance computing centers Local Area Networks Storage Area Networks Supporting 1& 10&40& 100& 400 Gb/s applications |

|

Coated with FCJ's proprietary dual layer UV curable acrylate |

Optimized performance in tight-buffer cable applications High resistance to micro-bending Stable performance over a wide range of environmental conditions |

Characteristics | Conditions | Specified values | Units |

Geometry Characteristics | |||

Core Diameter | - | 50±2.5 | [㎛] |

CoreNon-Circularity | - | ≤5.0 | [%] |

Cladding Diameter | - | 125.0±1.0 | [㎛] |

Cladding Non-Circularity | - | ≤0.6 | [%] |

Coating Diameter | - | 245 ±7 | [㎛] |

Coating/Cladding Concentricity Error | - | ≤10.0 | [㎛] |

Coating Non-Circularity | - | ≤6.0 | [%] |

Core/Cladding Concentricity Error | - | ≤1.0 | [㎛] |

Delivery Length | - | up to 8.8 | [km/reel] |

Optical Characteristics | |||

Attenuation | 850nm | ≤2.4 | [dB/km] |

1300nm | ≤0.6 | [dB/km] | |

- | - | OM2+/OM3/OM4 Bend Insensitive | |

Overfilled Modal Bandwidth | 850nm | ≥700/≥1500/≥3500 | [MHz•km] |

1300nm | ≥500/≥500/≥500 | [MHz•km] | |

Effective Modal Bandwidth | 850nm | ≥950/≥2000/≥4700 | [MHz•km] |

Application support distance on | - | - | - |

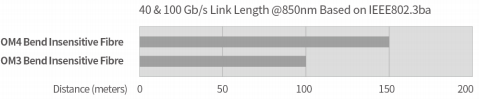

40GBASE-SR4 / 100GBASE-SR10 | 850nm | -/100/150 | [m] |

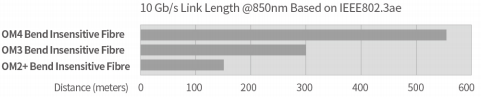

10GBASE-SR | 850nm | 150/300/500 | [m] |

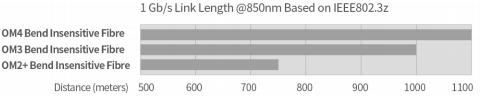

1000BASE-SR | 850nm | 750/1000/1100 | [m] |

DMD Specification | Compliant with and more stringent than the requirements of IEC60793-2-10 | - | |

NumericalAperture | - | 0.200±0.015 | - |

Group Refractive Index | 850nm | 1.482 | - |

1300nm | 1.477 | - | |

Zero Dispersion Wavelength,λ0 | - | 1295~1340 | [nm] |

Zero Dispersion Slope, S0 | 1295nm≤λ0≤131Onm | ≤0.105 | [ps/(nm2 • km)] |

131Onm≤λ0≤134Onm | ≤0.000375(1590-λ0) | [ps/(nm2 • km)] | |

Macrobending Loss1 | - | - | - |

2Turns@15mm Radius | 850nm | ≤0.1 | [dB] |

1300nm | ≤0.3 | [dB] | |

2Tums@7.5 mm Radius | 850nm | ≤0.2 | [dB] |

1300nm | ≤0.5 | [dB] | |

Backscatter Characteristics 1300nm | |||

Step (Mean of Bidirectional Measurement) | - | ≤0.10 | [dB] |

Irregularities Over Fibre Length and Point Discontinuity | - | ≤0.10 | [dB] |

Attenuation Uniformity | - | ≤0.08 | [dB/km] |

Environmental Characteristics 850nm & 1300nm | |||

Temperature Cycling | -60°C to 85°C | ≤0.10 | [dB/km] |

Temperature-Humidity Cycling | -10°C to 85°C,4% to 98% RH | ≤0.10 | [dB/km] |

Water Immersion | 23°C,30days | ≤0.10 | [dB/km] |

Dry Heat | 85°C,30days | ≤0.10 | [dB/km] |

Damp Heat | 85°C,85%RH,30days | ≤0.10 | [dB/km] |

Mechanical Specification | |||

Proof Test | - | ≥9.0 | [N] |

- | ≥1.0 | [%] | |

- | ≥100 | [kpsi] | |

Coating Strip Force | typical average force | 1.5 | [N] |

peak force | ≥1.3, ≤8.9 | [N] | |

Dynamic Stress Corrosion Susceptibility Parameter (nd, typical) | - | 20 | - |

Remarks: 1. The launch condition for the macrobending loss measurement fulfils that described in IEC61280-4-1.