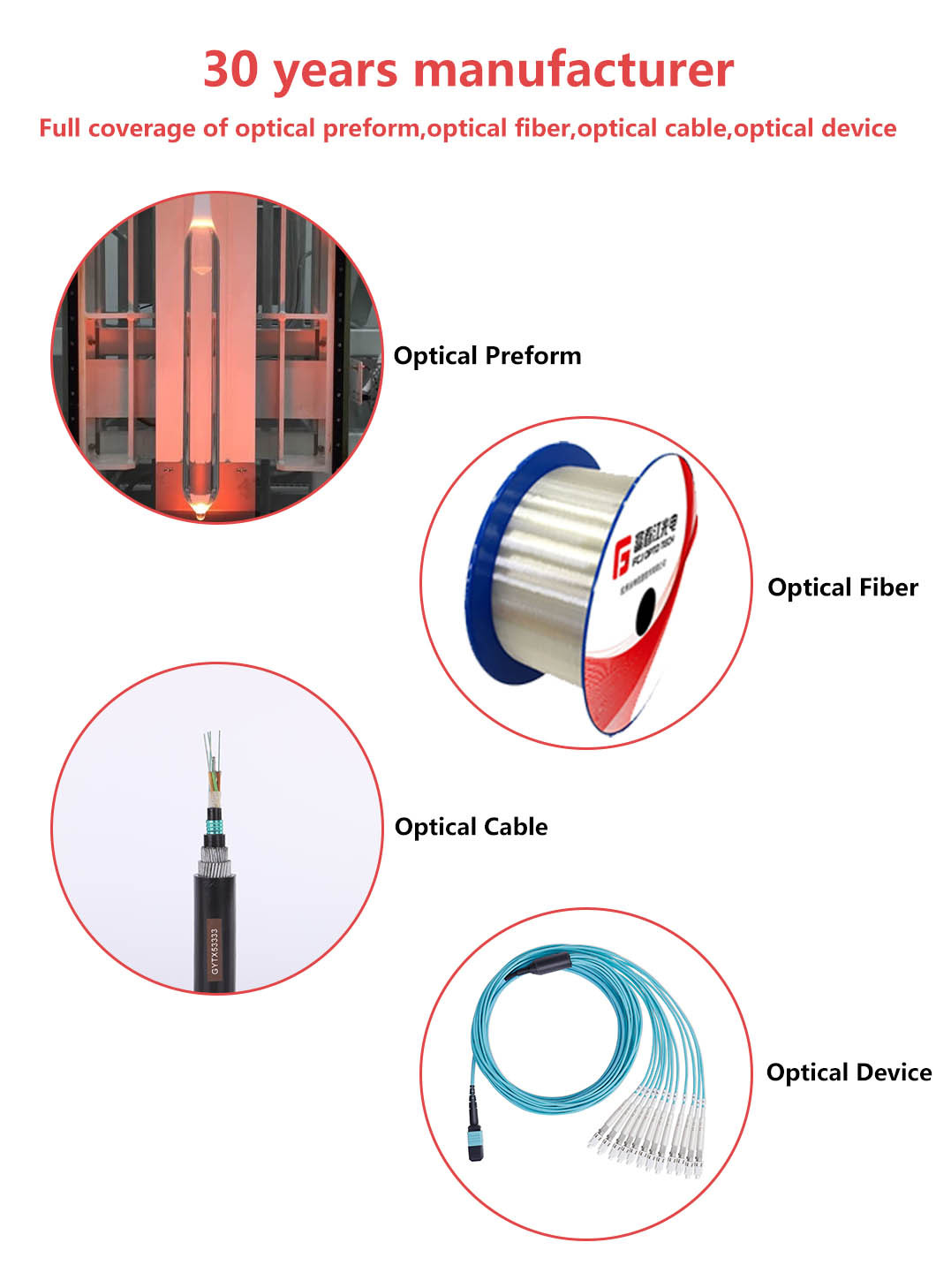

FCJ factory Stainless Steel Tube Sslt Opgw Fiber Cables From FCJ OPTO TECH

- Model

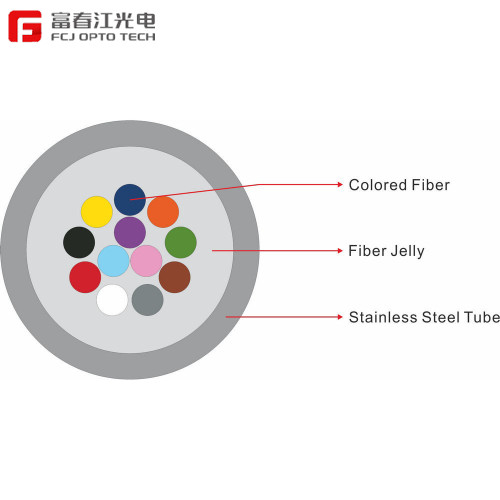

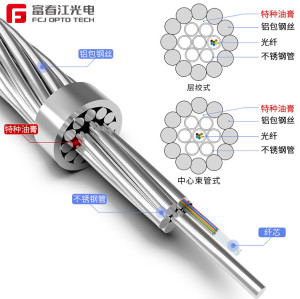

- Stainless Steel Tube

Item specifics

- Fiber Type

- G652D/Multimode

- Operating Temperature

- -40°C to + 70°C

- Installation

- Aerial/Direct Buried/Duct

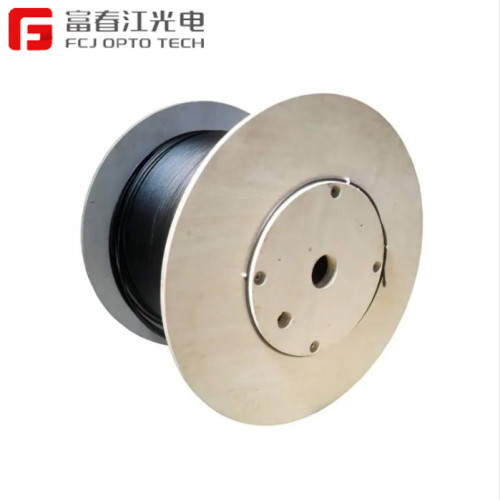

- Transport Package

- Wooden Drums or as Per Customers′ Requests

Review

Description

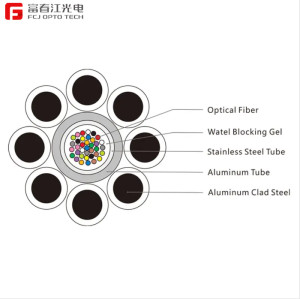

Stainless Steel Tube F-SST(Optical fiber composite stainless steel loose tube) is one kind of seamless tube, which is made of stainless steel, after laser longitudinal welding and jelly filling in the middle. With marvelous performance of longitudinal water resistance, the tube is perfect to maintain good protection of optical fiber. It is especially designed for harsh environments, and can be used for various applications from oil well to military, underwater, fire resistant, and anti-rodent facilities etc. It is suitable for the direct use or basis use or basic optical units of fiber cable.

Fire monitoring

Oil well exploration

Oil pipe monitoring and communication

Optical unit for multipurpose optical cable

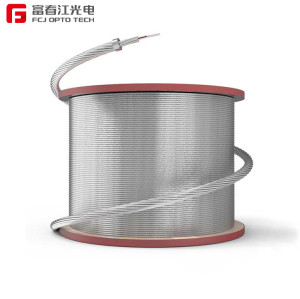

Small size and low weight

Good mechanical performance, withstanding the tensile force and force and super pressure

Waterproof, moisture-proof, anti-rodents,no rusty

Resistance to acid, alkali, salt corrsion

Non-toxic, flame retardant, fire and explosion proof

Outstanding high and low temperature performances

With excellent fire resistance, it can keep communication in the fire(800℃) more than 2 hours with normal optical fiber

Optical Characteristics

| G.652 | G.655 | 50/125 μm | 62.5 / 125 μm | |

Attenuation | @ 850nm |

|

| ≤3.0dB / km | ≤3.0dB / km |

| @ 1300nm |

|

| ≤1.0dB / km | ≤1.0dB / km |

| @ 1310nm | ≤0.36dB / km |

|

|

|

| @ 1550nm | ≤0.22dB / km | ≤0.23dB / km |

|

|

Bandwidth | @ 850 |

|

| ≥ 500MHZ · km | ≥ 500MHZ · km |

| @ 1300 |

|

| ≥1000MHZ · km | ≥600MHZ · km |

Numerical aperture |

|

|

| 0.200 ± 0.015NA | 0.275 ± 0.015 NA |

Cable cut-off wavelength |

| ≤1260nm | ≤1480nm |

| |

Fiber core number | structure size | Cable weight | Allow tension (N) | Allowing crush force (N) | |

Diameter d | Wall thickness t | Kg / km | Long-term / short-term | Long-term / short-term | |

1 | 0.90 | 0.18 | 3.38 | 140/280 | 2000/4000 |

2 | 1.20 | 0.18 | 4.95 | 160/320 | 2000/4000 |

4 | 1.35 | 0.18 | 5.75 | 250/500 | 2000/4000 |

6 | 1.50 | 0.18 | 6.58 | 270/540 | 2000/4000 |

8 | 1.80 | 0.20 | 8.99 | 350/700 | 1000/2000 |

12 | 2.00 | 0.20 | 10.27 | 400/800 | 1000/2000 |

24 | 2.40 | 0.20 | 12.88 | 500/1000 | 1000/2000 |

36 |

2.80 |

0.20 |

15.70 |

600/1200 |

1000/2000 |

48 |

3.40 |

0.30 |

26.90 |

650/1300 |

1000/2000 |

72 |

4.10 |

0.30 |

32.39 |

800/1800 |

1000/2000 |

96 |

4.60 |

0.30 |

36.34 |

900/1800 |

1000/2000 |

Operating temperature: -60~+80℃

Storage temperature: -60~+85℃