G.652D+G.657A1 Single mode optic fiber

- Model

- Single-Mode Optical Fiber G652D+G657A1

Item specifics

- Fiber Type

- G.652D+G657A1

- Operating Temperature

- -40°C to + 70°C

- Installation

- Aerial/Direct Buried/Duct

Review

Description

Low loss Bending-insensitive compatible Single-mode Fiber ( G.652D-LLBI )

The fiber complie with or exceed the technical specifications in ITU-T G.652.D /G657.A

- Superior anti-bending property.

- Reducing significantly the attenuation of the 1260~1625nm full band

- Fully compatible with G.652 single-mode fiber. Full band (1260~1626 nm) transmission.

- Low PMD for high bit-rate and long distance transmission. Extremely low micro-bending attenuation, applicable for all optical cable types including ribbons.

- High anti-fatigue parameter ensures service life under small bending radius

All cable constructions, 1260~1626nm full band transmission, including ribbon, loose tube stranded, slotted core,

central tube, tight buffered designs, FTTH high speed optical routing, optical cable in small bend radius,

small-size optical fiber cable and device.

|

Attributes |

specification |

||

|

Dimensional

Specifications |

Cladding Diameter |

125.0±0.7 um |

|

|

Cladding Non-Circularity |

≤0.7% |

||

|

Coating Diameter |

242±5 um |

||

|

Coating-Cladding

Concentricity |

≤12 um |

||

|

Coating Non-Circularity |

≤6 % |

||

|

Core-Clad Concentricity |

≤0.5 um |

||

|

Fiber Curl (radius) |

≥4 m |

||

|

Delivery Length |

2.05-50.4( km/reel) |

||

|

Optical Specifications |

Mode-Field Diameter (MFD) |

@1310nm |

9.2±0.4 um |

|

@1550nm |

10.4±0.5 um |

||

|

Attenuation |

@1310nm |

≤0.32 dB / km |

|

|

@1383nm |

≤0.32 dB / km |

||

|

@1550nm |

≤0.18 dB / km |

||

|

@1625nm |

≤0.20 dB / km |

||

|

|

Attenuation VS. Wavelength |

@1285-1330nm, Ref. λ@1310nm |

≤0.03dB / km |

|

@1525-1575nm, Ref. λ@1550nm |

≤0.02dB / km |

||

|

Point Discontinuity |

@1310nm |

≤0.05 dB |

|

|

@1550nm |

≤0.05 dB |

||

|

Polarization Mode Dispersion(PMD) |

Maximum Individual Fiber

PMD |

≤0.1 ps/(km1/2) |

|

|

PMD Link Design Value (M=20, Q=0.01%) |

≤0.06 ps/(km1/2) |

||

|

Typical Value |

0.04 ps/(km1/2) |

||

|

Zero Dispersion Wavelength(λ0) |

1312±12 nm |

||

|

Zero Dispersion Slope(S0) |

≤0.092 ps/(nm2.km) |

||

|

Dispersion |

1550nm |

≤18 ps/(nm.km) |

|

|

1625nm |

≤22 ps/(nm.km) |

||

|

Cable Cutoff Wavelength

λcc |

≤1260 nm |

||

|

Mechanical Specifications |

Proof Test |

≥9.0N, ≥1.0%, ≥100Kpsi |

|

|

Dynamic stress corrosion

susceptibility parameters Nd |

≥20 |

||

|

Coating Strip Force |

Average |

1.5 N |

|

|

Peak |

1.3-8.9 N |

||

|

Macrobend Loss |

1 turn,

Φ20mm@1550nm&1625nm |

≤0.5 dB,≤1.5

dB |

|

|

10 turns,

Φ30mm@1550nm&1625nm |

≤0.05 dB,≤0.3

dB |

||

|

Environmental Specifications |

Temperature Dependence(-60℃ to 85℃ ,@1310nm&1550nm&1625nm) |

≤0.05 dB / km |

|

|

Temperature humidity

cycling(-10℃to 85℃,98%RH@1550nm&1625nm) |

≤0.05 dB / km |

||

|

Water Immersion(23±2℃,

30 days@1310nm&1550nm&1625nm) |

≤0.05 dB / km |

||

|

Dry Heat Soak(85±2℃,

30 days@1310nm&1550nm&1625nm) |

≤0.05 dB / km |

||

|

Damp Heat(85±2℃,

at 85%RH, 30 days @1310nm&1550nm&1625nm) |

≤0.05 dB / km |

||

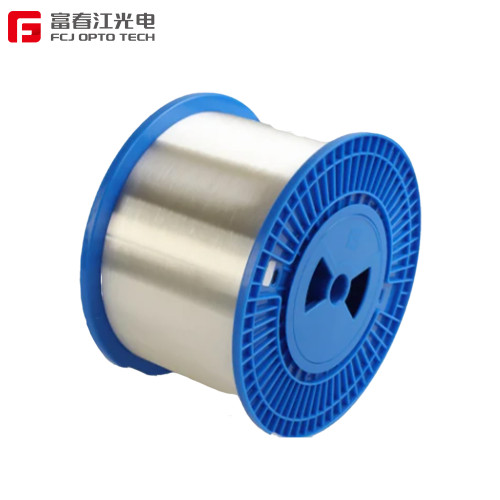

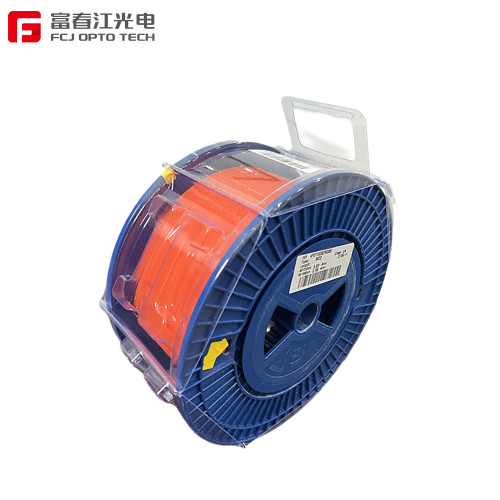

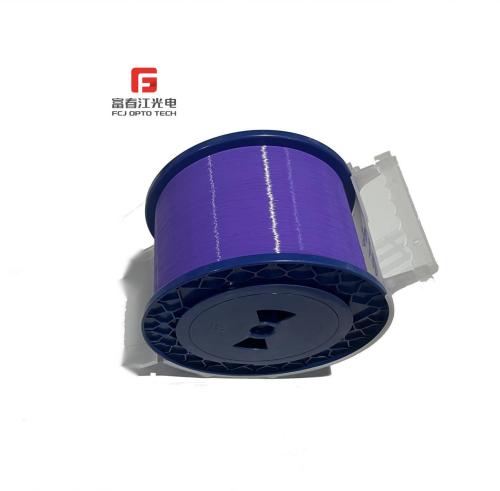

Ø Ensure

no foreign matter on the reel and fiber surface, wrap it with film and cover,

and label fiber coding on the reel and cover

respectively.

Ø The

packaged optical fiber is stored at a constant temperature of 25 ℃ in

a light-proof warehouse. The products are fixed in the carton when they are

shipped out of the warehouse. The carton number and fiber coding information

are attached to the carton, and the electronic test report is attached to each shipment.