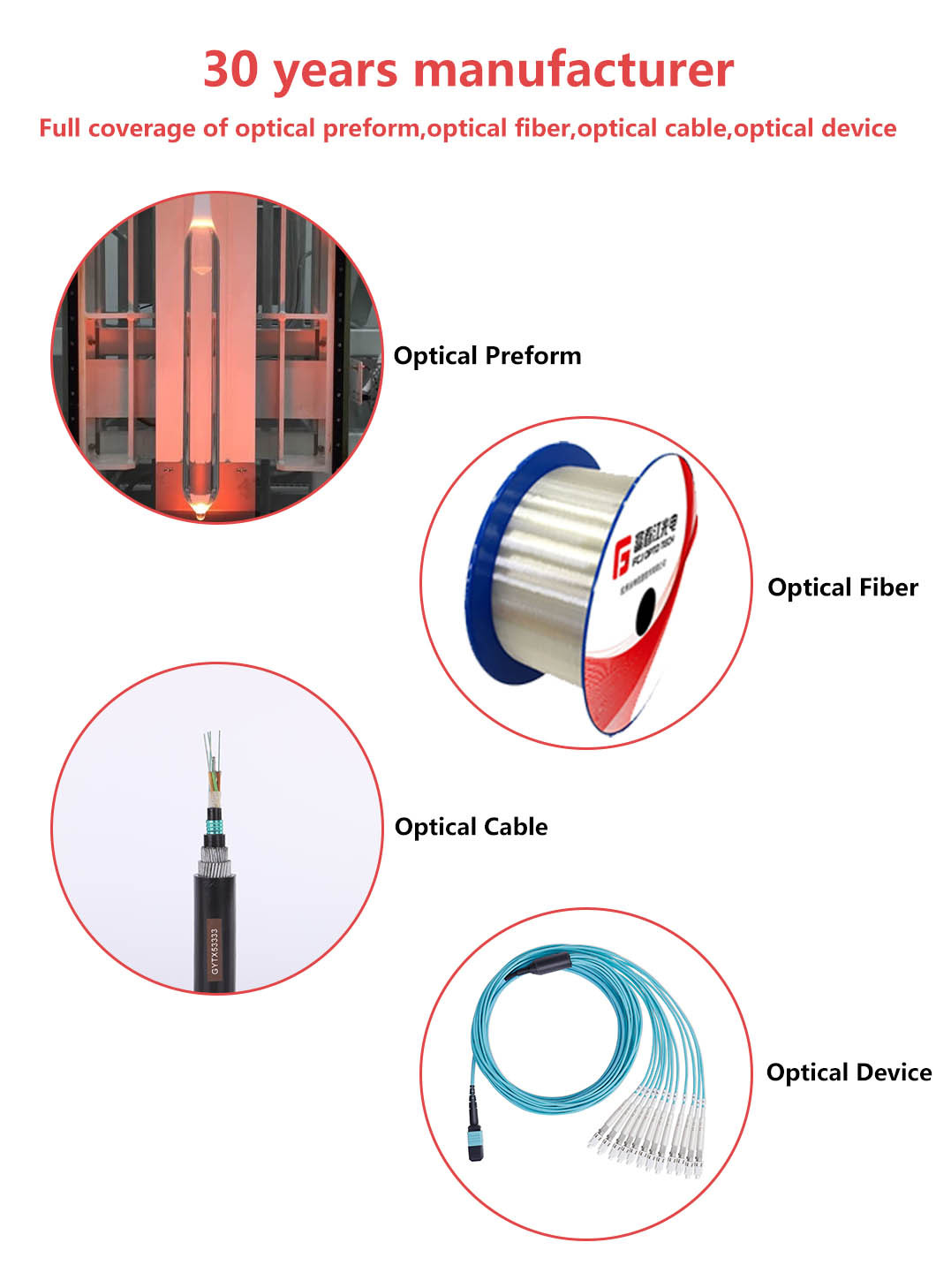

FCJ factory Optical Fiber (G. 652B) Non-Dispersion Shifted Single-Mode - FCJ OPTO TECH

- Model

- Optical Fiber (G. 652B)

Item specifics

- Fiber Type

- G. 652B

- Operating Temperature

- -40°C to + 70°C

- Installation

- Aerial/Direct Buried/Duct

Review

Description

Type

Single-Mode Optical Fiber (G. 652B)

Standard

Complies with or exceed the technical specifications in ITU-T G.652.B & IEC B1.1.

Features

- Low attenuation, dispersion and PMD, suitable for high bit-rate and long distance transmission.

Application

Suitable for all optical cable constructions, including ribbon, loose tube stranded, slotted core, central tube, tight buffered designs.

Technical Specifications

| Fiber Specifications | Main Indexes | Technical Parameter | ||

| Dimensions Specifications | Cladding Diameter | 125.0±1.0 um | ||

| Cladding non-circularity | ≤1 % | |||

| Coating diameter | 245±10 um | |||

| Coating/cladding concentricity error | ≤12 um | |||

| Coating non-circularity | ≤6 % | |||

| Core/cladding concentricity error | ≤0.6 um | |||

| Fiber curl (radius) | ≥4 m | |||

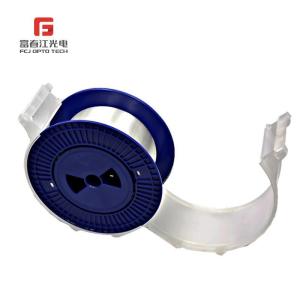

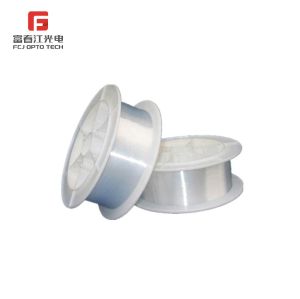

| Fiber lengths available | 2.1-24.45 km/spool | |||

| Optical Specifications | MFD | 1310nm | 9.2±0.4 um | |

| 1550nm | 10.4±0.6 um | |||

| Attenuation | 1310nm | ≤0.36 dB / km | ||

| 1550nm | ≤0.22 dB / km | |||

| 1625nm | ≤0.24 dB / km | |||

| Attenuation VS. Wavelength | 1285-1330nm, compared with 1310nm | ≤0.04 dB / km | ||

| 1525-1575nm, compared with 1550nm | ≤0.03 dB / km | |||

| Point Discontinuity | 1310nm | ≤0.05 dB | ||

| 1550nm | ≤0.05 dB | |||

| Polarization Mode Dispersion(PMD) | Maximum individual fiber | ≤0.2 ps/(km1/2) | ||

| PMD link design value(M=20,Q=0.01%) | ≤0.1 ps/(km1/2) | |||

| Typical value | 0.04 ps/(km1/2) | |||

| Zero-dispersion wavelength | 1312±12 nm | |||

| Dispersion slope | ≤0.091 ps/(nm2.km) | |||

| Dispersion in the range of wavelength | 1285~1339nm | ≤3.4 ps/(nm.km) | ||

| 1271~1360nm | ≤5.3 ps/(nm.km) | |||

| Cable cutoff wavelength λcc | ≤1260nm | |||

| Macrobend loss | 1turn Φ32mm, 1550nm | ≤0.05 dB | ||

| 100 turns Φ50mm, 1310nm&1550nm | ≤0.05 dB | |||

| 100 turns Φ60mm, 1625nm | ≤0.05 dB | |||

| Mechanical Specifications | Proof test | ≥9.0N, ≥1.0%, ≥100Kpsi | ||

| Fatigue Resistance Parameter Nd | ≥20 | |||

| Coating strip force | Average value | 1.5N | ||

| Peak value | 1.3-8.9N | |||

| Environmental Specifications | Temperature dependence (-60ºC to +85ºC, 1550nm&1625nm) | ≤0.05 dB / km | ||

| Temperature humidity cycling (-10ºC to +85ºC, at 85%RH, 1550nm&1625nm) | ≤0.05 dB / km | |||

| Water immersion (23±5ºC, 30 days, 1550nm&1625nm) | ≤0.05 dB / km | |||

| Heat aging(85±2ºC, 30 days, 1550nm&1625nm) | ≤0.05 dB / km | |||

| Damp Heat (85±2ºC at 85%RH, 1550nm&1625nm) | ≤0.05 dB / km | |||

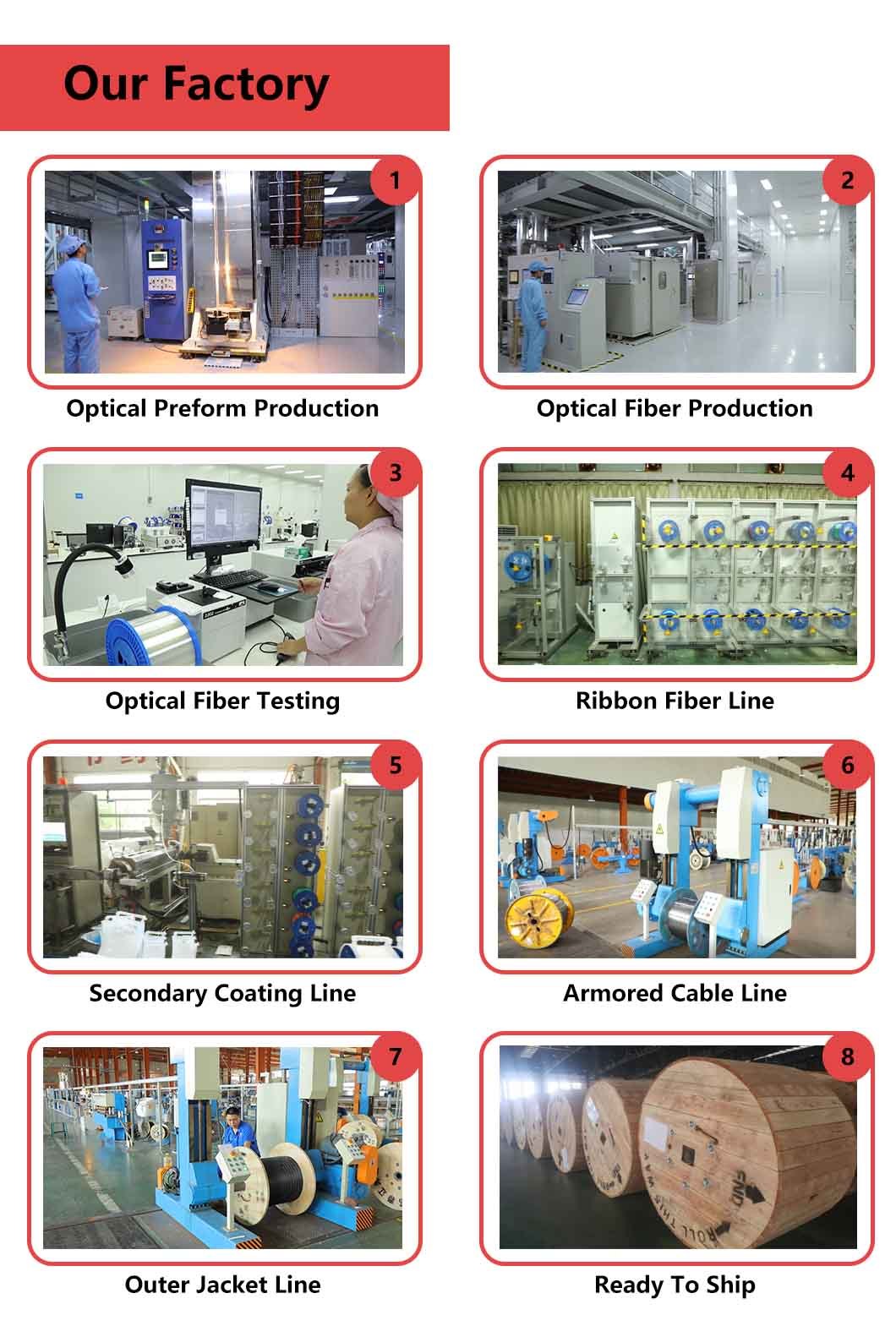

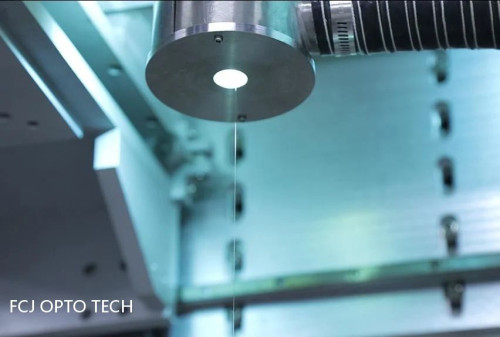

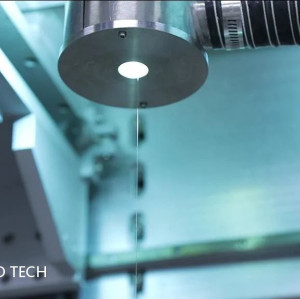

The company produces and tests optical fiber independently, all qualified fibers meet the requirements of technical specifications.

Packaging and storage